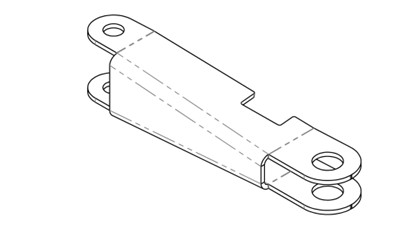

Brackets can be manufactured in various ways, such as casting or CNC machining. However, the best way to make simple supports is sheet metal. One of the most common sheet metal processes is bending, in which a machine called a brake is used to bend the sheet metal to a maximum angle of 120 °. This is probably the most important process when manufacturing sheet metal supports, because almost all supports contain at least one bend. Other sheet metal processes must also be used. Before any bending, the sheet metal must be cut to a certain size by using a machine such as a laser cutter or a plasma cutter. You can use a punch to punch holes in the bracket (for screws), and you may need to weld to add gusset plates or other features. In addition to the above sheet metal process, CNC machining can also be used to add more complex features to the support, especially for customized design of non-standard parts.

The support can be made of a variety of metals, depending on certain factors, including the load it must support, appearance requirements, surface treatment requirements, minimum and maximum thickness, required bending angle, and manufacturing budget. Click here to contact JIATONG.

QUICK LINKS:>>>Sheet Metal Frame | Sheet Metal Housing | Sheet Metal Chassis | Sheet Metal Cover | Sheet Metal Parts Components | China Sheet Metal Manufacturer | Custom Sheet Metal Parts | Sheet Metal Cabinet | China Sheet Metal Parts | Sheet Metal Bracket | Sheet Metal Parts Manufacturer | Sheet Metal Fabrication China | Metal Manufacturing in China | Metal Enclosure Manufacturers | Sheet Metal Cover | Sheet Metal China | Sheet Metal Enclosure

评论

发表评论